Ever wonder about the little line running down your board? You may have noticed it down the center line. There’s a lot that goes into surfboard construction and that little strip is a big part of it.

While it may just look decorative, the stringer on your board has a job to do as part of the overall construction. But what is it exactly and what is its purpose?

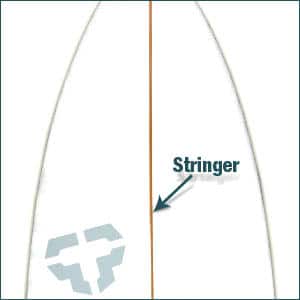

The stringer is a thin wooden strip, usually down the center of your board that adds stiffness and strength.

A stringer on a surfboard is the wooden strip running down the center of your board. Their job is to add strength and control the flex of a surfboard.

Flex is how much your surfboard bends. When board design moved to polyurethane and polystyrene foam cores, they needed something to add some strength and prevent the board from bending too far.

The addition of a wooden stringer solved this problem. Stringers are generally made from balsa wood, a soft, lightweight wood native to Central and South Americas although there are alternative materials used for stringers as well as alternative placements.

Flex and Stringer Placement

Before the use of foam cores, surfboards were made entirely out of wood. First they were made of hard, heavy woods like cedar and redwood, later to be replaced by the lightweight balsa.

While wooden surfboards still exist, in the sixties, the invention of synthetic foam revolutionised board construction. Foam cores have great buoyancy and are incredibly lightweight, however, they can snap easily on their own.

The addition of a stringer added necessary strength to the board, while still maintaining flex. This flex is important as it helps with projecting you forward through turns.

How a board flexes is important as it influences maneuverability, stability, speed and turns.

Your board curves slightly to fit the shape of the wave when pressure is applied down and releases as you drive up and the weight begins to lift.

The energy created by this bend and release projects and moves you forward.

Different placements of stringers allow surfboard shapers and manufacturers to control the level of flex and where it is in the board, affecting your surfing experience.

Thicker stringers add more stiffness, while thinner stringers leave more flex in the board. There can also be several thin stringers next to each for extra strength but with added aesthetic. This is aptly called a multiple stringer.

Often, big wave boards will have multiple stringers for added strength to their boards.

In the center of the board is the most commonly used stringer placement. This adds stiffness through the middle of the board, meaning it will feel strong where you stand.

Which is great as the center of your board takes the most pressure from your weight.

However, center stringers can leave the rails of your board softer meaning they can flex and twist differently from the rest of the board. This is called torsional flex and this twisting can slow you down.

To prevent this torsional flex, some boards have the stringer out towards the rails, following the curve of the rail instead of in a straight line.

This placement is called a parabolic stringer. It stiffens up the board along the rail lines providing more spring where your board meets the water during turns.

You can also have a wedge stringer, where two strips begin together at the nose and peel out from each other towards the tail. Or a flared stringer that starts at the nose and flares out off the rails.

Wherever a stringer is placed is for a specific effect in the flex of a board.

Stringer Materials

Today, there are many different types of materials that can be used for stringer construction.

Wood is the most often used material in stringer construction.

Balsa is touted as the traditional and most commonly used choice amongst the different types of wood. Balsa wood is very lightweight making it ideal for board construction.

While balsa is the most common there are other frequently used woods. Basswood, cedar, spruce, plywood and birch are all often used to make stringers in surfboard construction.

These all provide different levels of strength with flexibility. The choice of type of wood depends on a few factors. Namely the preference of the board manufacturer and cost.

In addition to these practical aspects, the type of waves a board is meant for affects choice as well. Some will need more flex than others.

Stringers can also be made of materials other than wood, including high density foam and PVC.

There are also stringers made of carbon fiber. Carbon fiber stringers can be found down the center line or wrapped entirely around the rails.

This newly used material has a good strength to weight ratio, meaning it’s lighter than wooden stringers with just as much strength.

There are also boards made without stringers altogether. Epoxy resin boards often don’t have a stringer. They rely on the strength of the foam they’re made of and layers of epoxy and fiberglass for strength. These are often referred to as pop out boards.

These boards generally have less flex than boards with a stringer. Something beginners may not notice but advanced surfers will feel. As a result, most veteran surfers prefer boards that require a stringer.

How Stringers are Made

General surfboard construction uses a foam “blank” to start. These blanks are a foam mold in the general shape of a surfboard. From this first mold, foam blanks will be shaved down and perfected into a board and are made of either polyurethane or expanded polystyrene.

Polyurethane is easier to work with during the shaving process, whereas polystyrene is challenging.

Once the mold has dried, it’s split lengthwise down the middle. From here, the stringer is then glued through the center of the foam and the blank is compressed back together.

But first, the stringer has to be constructed. Stringers are made using a thin piece of wood that is shaved and scraped into the proper shape, length and width.

Width is the most important aspect of the stringer as it’s where the strength comes from.

Boards 6 feet and under will most often have stringers 3/16 of an inch while longer boards generally have a stringer ⅜ of an inch.

Shorter boards naturally have less flex and therefore can use a thinner stringer. Longer boards on the other hand naturally have a lot of flex thanks to their extra length. In order to stay strong, they require a thicker stringer.

The general rule of thumb is the longer the board, the thicker the stringer. You can also make your own stringer if building your own board. There are stringer templates available or you can also make your own design.

Related Questions

How are Surfboards Made?

There are several different ways to make a surfboard. The most common begins with a foam blank. First, synthetic foam is placed into a mold and hardened.

Then depending on the manufacturer, this mold is split in two, a wooden stringer is placed down the center and the foam glued back together.

After this dries, either an epoxy or polyester resin is layered with fiberglass cloth over the outside of the foam.

This adds strength and waterproofing to the board. The foam used to make boards is highly absorbent so without this resin layer, it would become waterlogged.

Multiple resin layers give extra protection from dings and scratches that can cause your board to fill up with water.

Does a Surfboard Need a Stringer?

For most boards, the stringer is an essential part of construction.

By adding strength, it prevents the board from snapping in two from too much pressure, either from your own weight standing on the board or from the force of the waves.

However, there is an exception to this rule. Epoxy EPS boards often don’t need a stringer. Often referred to as pop out boards, these foam blanks in conjunction with the epoxy resin are strong enough without a stringer.

However, they are also much stiffer than other board construction. You can still use a stringer on epoxy boards.

Can You Make Your Own Surfboard?

Making your own surfboard is a fun project enjoyed by many surfers and builders alike. First requires getting the supplies needed, a foam blank, a stringer, shaping and sanding equipment and usually a template for design.

You may also need either epoxy or polyester resin to glass your board.

You can apply the resin layers yourself or have a professional do it for you after you’ve made your board shape. Either way, many people enjoy making and using their own board creations.